As you start out this year as an IT leader and you are trying to meet both project demand on one hand and savings goals on the other, remember to leverage what I term the IT ‘Flow of Work‘. Too often, once work comes into an organization, either through a new project going into production or through the original structure of the work, it is static. The work, whether it is server administration, batch job execution, or routine fixes, continues to be done by the same team that often developed it in the project cycle. Or at best, the system and its support are handed off to a dedicated run team, that continues to treat it as ‘custom’ work. In other words, once the system has been crafted by the project team, the regular work to run, maintain, and fix the system continues to be custom-crafted work.

This situation, where the work is static and continues to be executed by the initial, higher cost resources, would be analogous to a car company crafting a prototype or concept car, and then using that same team to produce every single subsequent car of that model with the same ‘craft’ approach. This of course does not happen as the car company moves the prototype to a production factory where the work is standardized and automated and leaned, and far lower cost resources execute the work. Yet in the IT industry we often fail to leverage this ‘flow of work’. We use senior server engineers to do basic server administration tasks (thus making it custom work). We fail to ‘package’ or productionalize or automate the tasks thus requiring exorbitant amounts of manual work because the project focused on delivering the feature and there was not optimization step to get it into the IT ‘factory’.

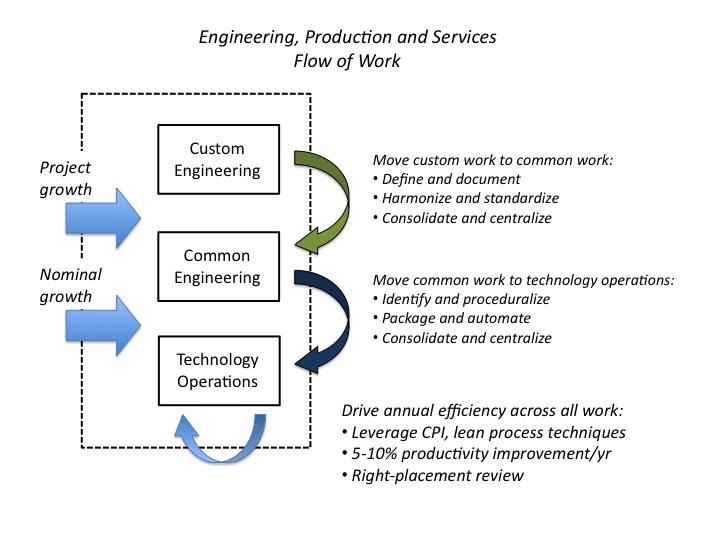

Below is a diagram that represents the flow of work that should occur in your IT organization.

The custom work, work done for new design, or complex analysis or maintenance, is the work done by your most capable and expensive resources. Yet, many IT organization waste these resources by doing custom work where it doesn’t matter. A case in point would be anywhere that you have IT projects leveraging custom designed and built servers/storage/middleware (custom work) instead of standardized templates (common work). And rarely do you see those tasks documented and automated such that they can be executed by the IT Operations team (routine work). And not only do you then waste your best resources on design that adds minimal business value, you then do not have those best resources available to do the new projects and initiatives the business needs to have done. Or similarly, your senior and high cost engineers are doing routine administrative work because that is how the work was implemented in production. Later, no investment has been made to document or package up this routine work so it can easily be done by your junior or mid-level engineering resources.

Further, I would suggest that you often find the common or routine engineering work stays in that domain. Investment is infrequently made to further shrinkwrap and automate and document the routine administrative tasks your mid-level engineers so that you can hand it off to the IT Operations staff to execute as part of their regular routine (and by the way, the Ops team typically executes these tasks with much greater precision than the engineering teams).

So, rather than fall into the traps of having static pools of work within your organization, drive and investment so that the work can be continually packaged and executed at a more optimal level and free up your specialty resources to tackle more business problems. Set a bar for each of your teams for productivity improvements. Enable them the time and investment to package the work and send it to the optimal pool. Encourage your teams to partner with the group that will receive their work on the next step of the flow. And make sure they understand that for every bit of more routine work that they can transition to their partner team, they will receive more rewarding custom work.

After a few cycles of executing the flow of work within your organization, you will find you have gained significant capacity and reduced your cost to execute routine work substantially. This enables you to achieve a much improved ratio of run cost versus build costs by continually compressing the run costs.

I have seen this approach executed with great effect in both large and mid-sized organizations. Have you been part of or lead similar exercises? What results did you see?

Best, Jim